1. Raw Cashmere Collection Our sourcing begins in the Mongolian countryside, where nomadic herders collect the soft undercoat from Hircus goats. We work directly with local communities to ensure ethical practices and the highest quality fibers.

2. Washing (Scouring) The raw cashmere is gently washed to remove grease, dust, and impurities. This step prepares the fiber for further processing while preserving its natural softness and structure.

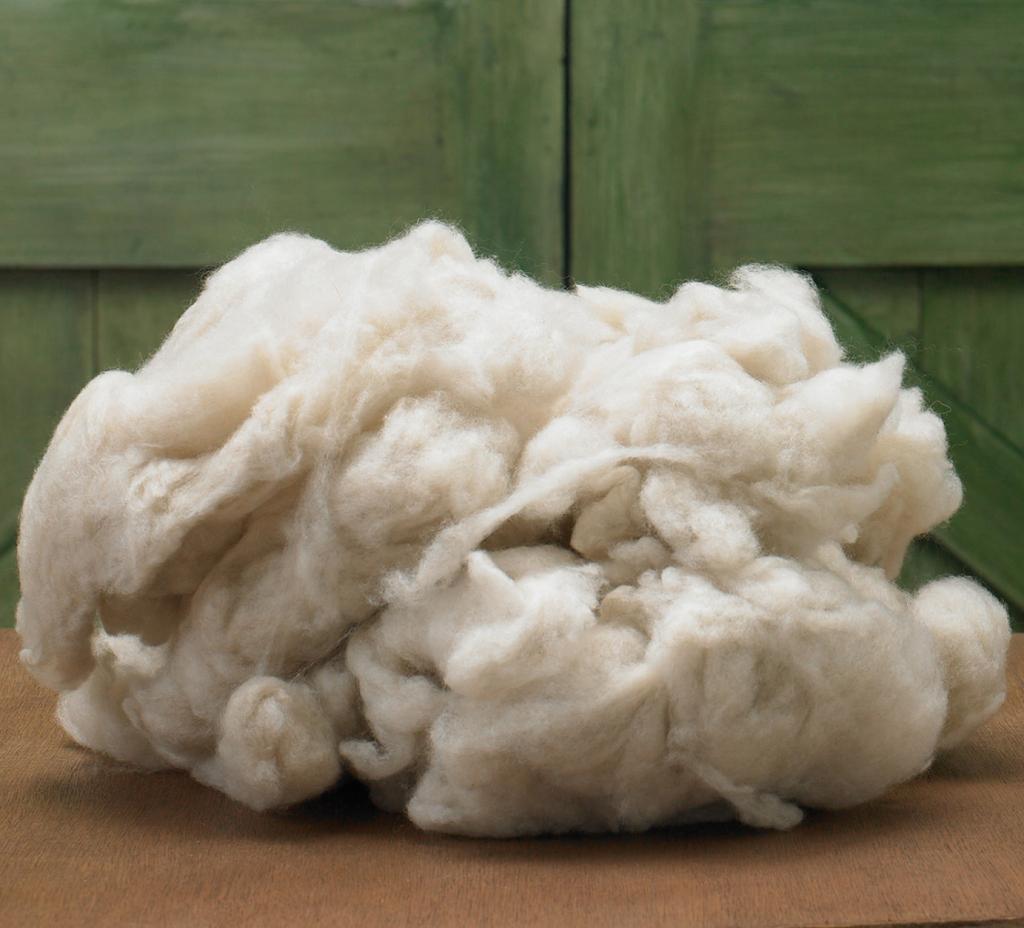

3. Dehairing In this critical stage, coarse guard hairs and debris are separated from the fine cashmere fibers using precision equipment. What remains is ultra-soft, high-grade dehaired cashmere.

4. Carding The dehaired fibers are aligned and cleaned further in preparation for spinning. This mechanical process ensures uniformity and smooth texture in the final yarn.

5. Spinning We transform the prepared fibers into yarn through controlled spinning. This stage determines the thickness, twist, and strength of the final product.

6. Twisting (if needed) For added strength or to meet specific client requirements, single yarns may be twisted together. This creates a more durable and versatile textile base.

7. Dyeing Cashmere yarns may be dyed in various shades according to customer preference. We use eco-friendly, colorfast dyes that maintain the fiber’s softness and purity.

8. Knitting / Weaving Depending on the intended application, the yarns are knitted or woven into textile forms. This is the point where raw material begins its transformation into product.

9. Linking / Assembling In this phase, different pieces or components are joined together — either by hand or machine — with precision and care.

10. Washing & Finishing The fabric or product is washed again to soften the texture and eliminate any residual chemicals. A finishing treatment gives it the desired touch and drape.

11. Ironing & Steaming Each item is carefully ironed or steamed to remove wrinkles and enhance its visual appeal — readying it for presentation or packing.

12. Quality Control Before shipping, each batch undergoes stringent quality checks. We ensure consistency in softness, length, color, and cleanliness.

13. Packing & Labeling Finally, the cashmere is neatly packed and labeled for export. Labels contain full traceability details and comply with destination regulations.